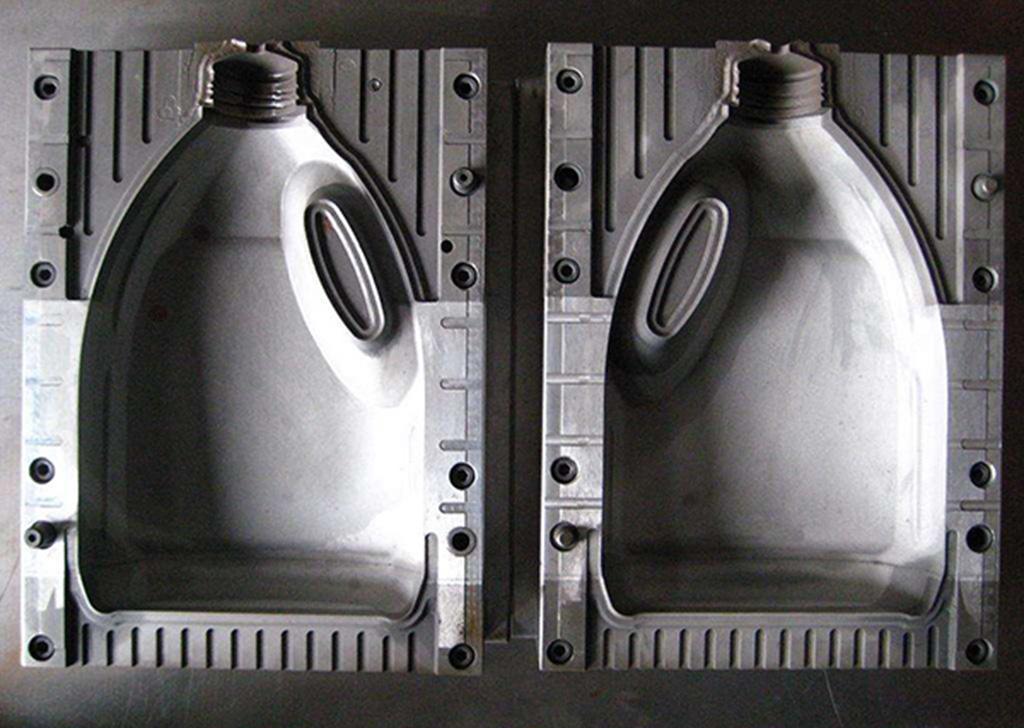

Our blow moulds for bottles are made from high-quality alloy steel, stainless steel, and aerospace-grade aluminum. Utilizing advanced CNC machining and precision coordinate measuring instruments, we ensure tight dimensional accuracy and consistent bottle production. This guarantees product quality and facilitates seamless integration into downstream processes like filling and capping automation.

We offer moulds designed for blow moulding processes, ensuring high dimensional accuracy across various applications. With precise mould design, advanced manufacturing techniques, and meticulous control of forming parameters, our moulds minimize dimensional deviations to meet strict industry requirements.

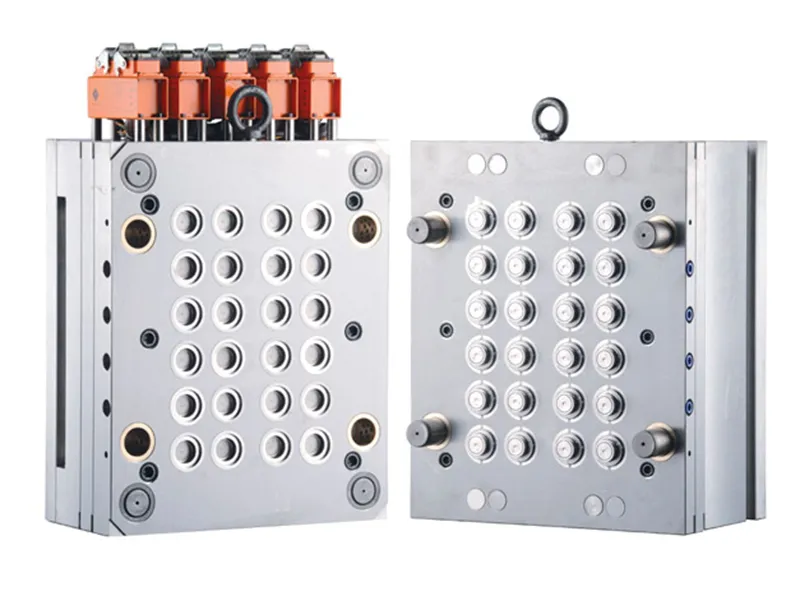

We not only provide blow moulding machines, but also offer custom PET preform moulds for our customers. Moulds are crucial in the moulding process because they ensure high consistency and precision in the products.

We can custom-produce various sizes of cap and closure moulds for manufacturing various bottle caps and container lids, widely used in the food and beverage, cosmetics, and pharmaceutical industries. The design and manufacturing quality of our cap and closure moulds ensure high performance, strong sealing, and attractive appearance of the final products.

Reach out to us to request detailed information about our molding machines to find the right fit for you!