Our high-speed stretch blow moulding machine is designed for efficient plastic bottle production, with an hourly output of 8,000 to 20,000 bottles, offering significant speed and efficiency advantages. It is widely used in industries requiring mass production of plastic bottles, such as beverages, food, cosmetics, and pharmaceuticals.

Our fully automatic stretch blow moulding machines are industrial equipment used for manufacturing plastic bottles by heating and blow moulding plastic pellets (usually PET) into various shapes (round, square, or flat) and sizes (100-500ML, 1L-5L, or 5L-10L).

Our PET jar stretch blow moulding machine is an industrial device specifically designed for manufacturing wide-mouth containers. With our excellent processing and manufacturing capabilities, our machines can produce jars with neck diameters ranging from 60mm to 180mm and can be customized according to customers’ actual needs.

The 1-12L container extrusion blow moulding machines, designed for producing small-capacity hollow plastic containers, are widely used for manufacturing common products in daily life and industrial sectors, such as small plastic bottles, cosmetic bottles, and pharmaceutical containers.

The 10-100L container extrusion blow moulding machine is primarily used for producing medium-capacity hollow plastic containers, such as 10L-100L plastic barrels, containers, and tanks.

The 120-1000L container extrusion blow moulding machine is designed for producing large hollow plastic containers like chemical barrels, water tanks, and automotive fuel tanks.

Our shampoo and detergent bottle extrusion blow moulding machines are specialized equipment for producing packaging containers for daily chemicals, including shampoo, lotion, and skincare bottles.

Our gallon bottle extrusion blow moulding machines are specialized equipment for producing large-capacity water containers.

Our chemical drum extrusion blow moulding machines are specifically designed for producing large plastic drums for storing and transporting chemicals.

Our PET preform injection moulding machines, also known as a bottle preform injection moulding machines, are specifically designed for manufacturing plastic preforms used to produce PET bottles, such as beverage bottles, mineral water bottles, and cosmetic bottles.

Our cap and closure injection moulding machines are specialized equipment for producing plastic bottle caps, widely used in packaging for beverages, personal care, food, and pharmaceuticals.

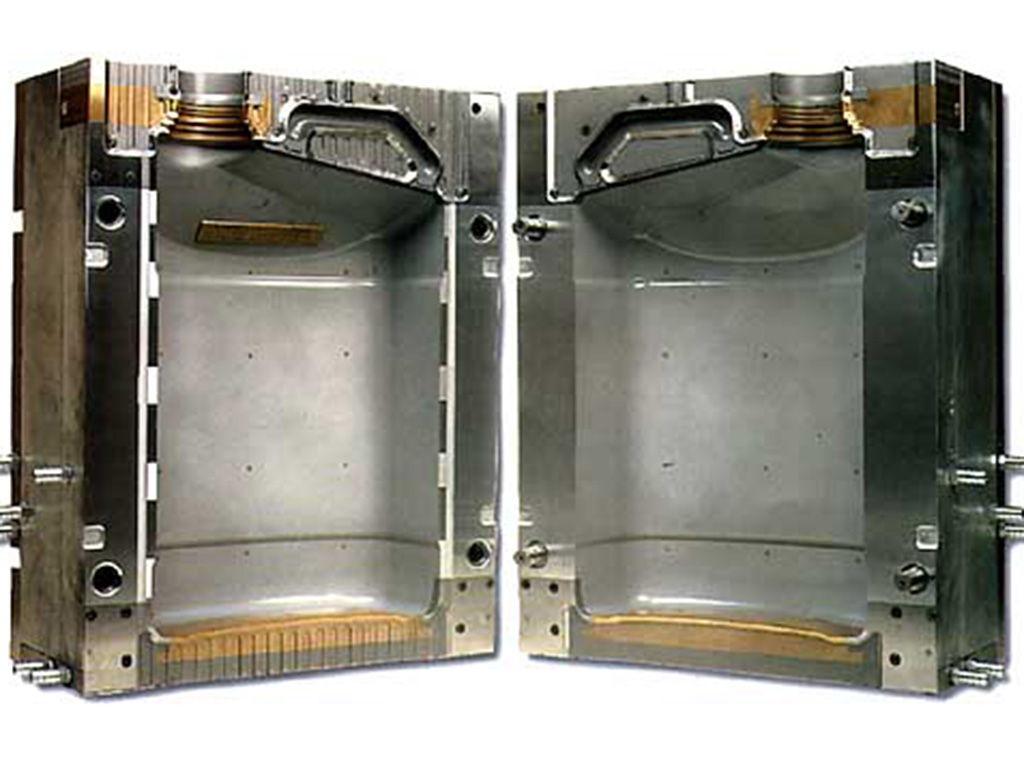

Our blow moulds for bottles are made from high-quality alloy steel, stainless steel, and aerospace-grade aluminum. Utilizing advanced CNC machining and precision coordinate measuring instruments, we ensure tight dimensional accuracy and consistent bottle production.

We offer moulds designed for blow moulding processes, ensuring high dimensional accuracy across various applications. With precise mould design, advanced manufacturing techniques, and meticulous control of forming parameters, our moulds minimize dimensional deviations to meet strict industry requirements.

We not only provide blow moulding machines, but also offer custom PET preform moulds for our customers.

We can custom-produce various sizes of cap and closure moulds for manufacturing various bottle caps and container lids, widely used in the food and beverage, cosmetics, and pharmaceutical industries.

For stretch blow moulding machine and extrusion blow moulding machine production lines

We enable full automation from extrusion and stretch blow moulding to packaging, providing comprehensive monitoring and management of the production process, which helps to optimize the entire production flow and achieve intelligent manufacturing.

Based on our customers’ actual situation and specific needs, we provide targeted solutions, with a portfolio of needs analysis, solution design, equipment upgrading, system integration, training acceptance, and continuous improvement.

With 100 pieces of process equipment, we can produce 500 blow moulding machines and 200 sets of preform moulds annually, ensuring timely delivery of customer orders.

We have over 20 years of experience in manufacturing blow moulding machines and PET preform moulds. Our machines and moulds are exported to more than 100 countries, including Indonesia, Malaysia, Saudi Arabia, Kenya, Tanzania, Nigeria, the USA, Mexico, Argentina, and Chile.

Our blow moulding machine frames and platforms are much heavier than others, ensuring no shaking during bottle production.

We precisely process and handle every part of our blow moulding machines and moulds, ensuring that every component of our blow moulding machines is carefully selected and handled with precision.