We are a distinguished equipment manufacturer specializing in the production of stretch/extrusion blow moulding machines and injection moulding machines, providing one-stop solutions that encompass design, production, and sales. Our machines are suitable for producing various plastic bottles with capacities ranging from 5ml to 40L, using PET, PP, and PE plastics. The produced bottles are widely used in industries such as drinking water, beverages, dairy products, household and personal care, chemicals, and medical products.

With nearly 20 years of experience in blow moulding machines and moulds, we have earned widespread support and praise from domestic and international customers for our high-quality products, reliable performance, and excellent value. Our team of over 10 senior engineers, specializing in blow moulding machines and mould design, has significantly contributed to equipment upgrades, innovations, and the development of new products. We hold full CE, ISO, and SGS certifications. With numerous skilled technicians and workers, we ensure the quality of our equipment and timely delivery. We also provide a comprehensive after-sales service system, offering free guidance, installation, training, and lifelong technical support.

Maiwei Machinery covers an area of over 3,000 square meters, with more than 20 advanced manufacturing machines. We deliver over 300 blow moulding machines and moulds annually, with products exported to more than 80 countries in Africa, South Asia, the Middle East, South America, and Eastern Europe.

Our high-speed stretch blow moulding machine is designed for efficient plastic bottle production, with an hourly output of 8,000 to 20,000 bottles, offering significant speed and efficiency advantages.

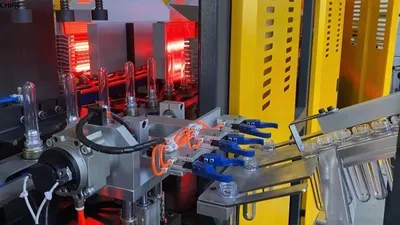

Our fully automatic stretch blow moulding machines are industrial equipment used for manufacturing plastic bottles by heating and blow moulding plastic pellets (usually PET) into various shapes (round, square, or flat) and sizes (100-500ML, 1L-5L, or 5L-10L).

Our PET jar stretch blow moulding machine is an industrial device specifically designed for manufacturing wide-mouth containers. With our excellent processing and manufacturing capabilities, our machines can produce jars with neck diameters ranging from 60mm to 180mm and can be customized according to customers’ actual needs.

The 1-12L container extrusion blow moulding machines, designed for producing small-capacity hollow plastic containers, are widely used for manufacturing common products in daily life and industrial sectors, such as small plastic bottles, cosmetic bottles, and pharmaceutical containers.

The 10-100L container extrusion blow moulding machine is primarily used for producing medium-capacity hollow plastic containers, such as 10L-100L plastic barrels, containers, and tanks.

The 120-1000L container extrusion blow moulding machine is designed for producing large hollow plastic containers like chemical barrels, water tanks, and automotive fuel tanks.

Our shampoo and detergent bottle extrusion blow moulding machines are specialized equipment for producing packaging containers for daily chemicals, including shampoo, lotion, and skincare bottles.

Our gallon bottle extrusion blow moulding machines are specialized equipment for producing large-capacity water containers. Using extrusion blow moulding, the machines process thermoplastic plastics into hollow water bottles that are widely used for packaging drinking water, chemical products, and other liquids.

Our chemical drum extrusion blow moulding machines are specifically designed for producing large plastic drums for storing and transporting chemicals. These drums require high strength, corrosion resistance, chemical resistance, and leak-proof characteristics, which our machines meet perfectly.

With the growing consumer demand for healthy drinking water, the drinking water market is continuously expanding, offering more market share and sales opportunities for water bottle production companies. By leveraging innovative designs and eco-friendly materials, companies can establish a unique brand image in the market and attract more consumer attention.

Currently, there are various dairy products worldwide, owing to different dietary habits, existing dairy processing technologies, market demand, and social and cultural environments. Increasing income, population growth, and urbanization all play a role in changing dietary preferences. Particularly, in developing countries, the demand for dairy products is steadily increasing. Therefore, the design and production of dairy containers are especially important.

Carbonated beverages have a global demand. As consumer needs grow, the production design of carbonated beverage bottles requires greater flexibility and higher output, while consumers seeking healthier, more eco-friendly, and hygienic bottles. The key is to design a blow moulding machine that meets these demands with high efficiency, quality, minimal resource waste, and low environmental costs.

The application of PET bottles has been expanding, from carbonated beverages and water to tea drinks. With technological advancements, using PE bottles for alcoholic beverages has become popular. Compared to traditional glass beer bottles, plastic beer bottles offer significant advantages as they are lightweight, shatterproof, explosion-resistant, with lower storage and transportation costs.

The household and personal care sector has numerous bottle specifications, covering all types of primary packaging (regular bottles, unique containers, jars, soft packaging). For filling specific products like hair/oral/skin care products, cosmetics, dishwashing liquid, and surface/laundry care in PET containers, we can help our customers unlock brand potential with innovative bottle solutions that enhance product performance.

Chemical products, including various detergents, corrosives, and chemical reagents, require high-quality and corrosion-resistant packaging due to their unique chemical properties. Given that the diverse chemicals need specific packaging, each chemical container must meet compatibility and specific operational requirements.

In recent years, with increasing environmental awareness and upgraded safety standards for pharmaceutical packaging, the medicine bottle industry faces numerous challenges and opportunities. Stricter environmental regulations require pharmaceutical bottle manufacturers to adopt more eco-friendly measures in material selection, production processes, and waste management, pushing the industry to continuously improve product quality and performance to meet more stringent market demands.