We focus on customer needs, providing comprehensive pre-sales and after-sales services, including online consultations and on-site guidance. We offer not only equipment but also bottle design, factory layout design, and beverage processing solutions, delivering full-service support.

We prepare a detailed quotation based on the design plan and market conditions, covering equipment pricing, delivery times, and after-sales services.

We negotiate with the customer on pricing, technical plans, payment terms, and delivery schedules. Once an agreement is reached, we sign the contract.

We deliver the equipment to the customer’s designated location according to the agreed delivery time.

We dispatch technicians to the customer site to install and test-adjust the equipment, ensuring that it operates correctly and meets expected production outcomes.

We provide training for the customer’s personnel on equipment operation, maintenance, and care, ensuring that they can use the equipment proficiently.

Our technical support and consultation services help resolve any issues the customer may encounter during operation.

We collect and reflect on customer feedback regarding our equipment and services to better understand their needs and expectations, thus continually improving our service.

Based on customer feedback and market changes, we continuously refine our products and services to enhance customer satisfaction and market competitiveness.

From Preforms to Bottles and Molds – Maiwei is Your Partner in Molding Technology

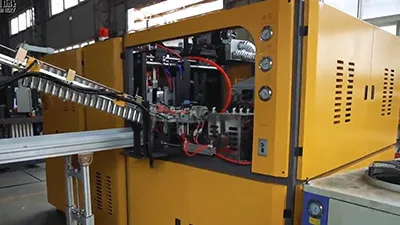

The 1-12L container extrusion blow moulding machines, designed for producing small-capacity hollow plastic containers, are widely used for manufacturing common products in daily life and industrial sectors, such as small plastic bottles, cosmetic bottles, and pharmaceutical containers.

The 10-100L container extrusion blow moulding machine is primarily used for producing medium-capacity hollow plastic containers, such as 10L-100L plastic barrels, containers, and tanks.

The 120-1000L container extrusion blow moulding machine is designed for producing large hollow plastic containers like chemical barrels, water tanks, and automotive fuel tanks.

Our shampoo and detergent bottle extrusion blow moulding machines are specialized equipment for producing packaging containers for daily chemicals, including shampoo, lotion, and skincare bottles.